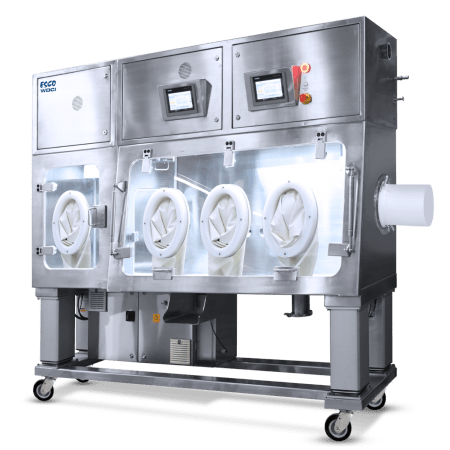

Weighing and Dispensing Containment Isolator (WDCI)

AED 0.00

The Esco Weighing and Dispensing Containment Isolators (WDCI) are advanced containment systems providing controlled negative pressure environments to maximize personnel protection during weighing and dispensing of potent compounds.

Esco WDCIs’ provide standard configurable designs that are able to adapt to various weighing and dispensing quantities and accuracies.

NOTE: No Exchange No Return Learn More

Warranty: 1 year from the delivery date, covering manufacturing defects. It does not cover breakage or misuse.

Quality is our priority. Our laboratory equipment is built for precision, durability, and dependable performance, ensuring consistent, reliable support for all your scientific needs.

Available on backorder

- Fully welded single-piece SS316L internal chambers with rounded coved corners

- Pressure tested to ISO 14644-7

- Inflatable antibacterial, USP Class VI compliant and food grade FDA approved gaskets providing both proactive and reactive sealing

- Safe change glove system allowing change of gloves whilst maintaining a contained system

- Integrated anti-vibration granite platform for analytical balance placement

- Integrated automated pressure decay testing

- Clean interior and exterior finishing

- Safe change filters to allow in-process filter replacement

- Lighting external to isolator chamber for ease of servicing and process chamber cleanliness

- Integrated automated height adjustment providing 280mm of motion for ergonomic comfort

|

GENERAL SPECIFICATIONS |

WDCI – 2G |

WDCI – 3G |

WDCI – 4G |

WDCI – 5G |

|

|

Nominal Size Process Chamber |

1190 mm (46.9”) |

1590 mm (62.8”) |

1990 mm (78.3”) |

2390 mm (94.1”) |

|

|

External Dimensions |

Without Base Stand |

1200 x 800 x 1730 mm (47.2” x 31.4” x 68.1”) |

1600 x 800 x 1730 mm (62.9” x 31.4” x 68.1”) |

2000 x 800 x 1730 mm (78.7” x 31.4” x 68.1”) |

2400 x 800 x 1730 mm (94.4” x 31.4” x 68.1”) |

|

With Adjustable Base Stand (Min) |

1200 x 800 x 2080 mm (47.2” x 31.4” x 81.8”) |

1600 x 800 x 2080 mm (62.9” x 31.4” x 81.8”) |

2000 x 800 x 2080 mm (78.7” x 31.4” x 81.8”) |

2400 x 800 x 2080 mm (94.4” x 31.4” x 81.8”) |

|

|

With Adjustable Base Stand (Max) |

1200 x 800 x 2360 mm (47.2” x 31.4” x 92.9”) |

1600 x 800 x 2360 mm (62.9” x 31.4” x 92.9”) |

2000 x 800 x 2360 mm (78.7” x 31.4” x 92.9”) |

2400 x 800 x 2360 mm (94.4” x 31.4” x 92.9”) |

|

|

Internal Dimensions (W x D x H) |

1190 x 633 x 842 mm (46.9” x 24.9” x 33.1”) |

1590 x 633 x 842 mm (62.8” x 24.9” x 33.1”) |

1990 x 633 x 842 mm (78.3” x 24.9” x 33.1”) |

2390 x 633 x 842 mm (94.1” x 24.9” x 33.1”) |

|

|

Glove Port Height Min |

950 mm (37.4”) |

950 mm (37.4”) |

950 mm (37.4”) |

950 mm (37.4”) |

|

|

Glove Port Height Max |

1300 mm (51.1”) |

1300 mm (51.1”) |

1300 mm (51.1”) |

1300 mm (51.1”) |

|

|

Chamber Pressure |

Negative Pressure |

Negative Pressure |

Negative Pressure |

Negative Pressure |

|

|

Airflow Type |

Turbulent Flow |

Turbulent Flow |

Turbulent Flow |

Turbulent Flow |

|

|

Airflow Volume – Maximum |

21 m3/h |

21 m3/h |

21 m3/h |

21 m3/h |

|

|

Airflow Volume – Maximum |

75 m3/h |

75 m3/h |

75 m3/h |

75 m3/h |

|

|

Filter Type – Inlet |

H14 Cartridge Filter with PVC Shroud |

H14 Cartridge Filter with PVC Shroud |

H14 Cartridge Filter with PVC Shroud |

H14 Cartridge Filter with PVC Shroud |

|

|

Filter Efficiency – Inlet – Safe Change |

99.999% |

99.999% |

99.999% |

99.999% |

|

|

Filter Efficiency – Exhaust – Safe Change |

H14 Push Push Filter with SS 316L Housing |

H14 Push Push Filter with SS 316L Housing |

H14 Push Push Filter with SS 316L Housing |

H14 Push Push Filter with SS 316L Housing |

|

|

Lighting Level |

≥ 650 lux (≥ 60 foot-candles) |

≥ 650 lux (≥ 603 foot-candles) |

≥ 650 lux (≥ 60 foot-candles) |

≥ 650 lux (≥ 60 foot-candles) |

|

|

Sound Level |

≤ 68 dBA |

≤ 68 dBA |

≤ 68 dBA |

≤ 68 dBA |

|

|

Isolator Construction |

Chamber |

SS 316L |

SS 316L |

SS 316L |

SS 316L |

|

Service Housing |

SS 304 |

SS 304 |

SS 304 |

SS 304 |

|

|

Support Frame |

SS 304 |

SS 304 |

SS 304 |

SS 304 |

|

|

Anti vibration weighing mount |

Black Granite for Analytical Weigh Scale |

✔ |

✔ |

✔ |

✔ |

|

Isolator Finish |

Chamber Internal |

≤ 0.4 Ra |

≤ 0.4 Ra |

≤ 0.4 Ra |

≤ 0.4 Ra |

|

Chamber External |

≤ 0.6 Ra |

≤ 0.6 Ra |

≤ 0.6 Ra |

≤ 0.6 Ra |

|

|

Service Housing External |

0.6 Ra |

0.6 Ra |

0.6 Ra |

0.6 Ra |

|

|

Support Frame |

1.0 Ra |

1.0 Ra |

1.0 Ra |

1.0 Ra |

|

|

Controls |

Color 6” HMI – Siemens – CE Marked |

✔ |

✔ |

✔ |

✔ |

|

Operator Specific Login sets Isolator Working |

✔ |

✔ |

✔ |

✔ |

|

|

Electrical Requirements |

110-120 V, AC, 50 Hz/60 Hz, 1Ø |

✔ |

✔ |

✔ |

✔ |

|

220-240 V, AC, 50 Hz/60 Hz, 1Ø |

✔ |

✔ |

✔ |

✔ |

|

|

480 V, AC, 50 Hz/60 Hz, 3Ø |

✔ |

✔ |

✔ |

✔ |

|

|

Compressed Air requirements |

6 Barg Pressure at 5Itr/sec |

✔ |

✔ |

✔ |

✔ |

|

Exhaust Duct Requirements (By Client) – Thimble Connection Required |

101.6 mm (4”) |

101.6 mm (4”) |

101.6 mm (4”) |

101.6 mm (4”) |

|

Built-in options

- System comes with optional inert environment software

- Fully welded or gasket sealed Rapid Transfer Port (RTP) adaptor is included allowing future expansion or reduction of the pass-through diameter

- System comes with built-in wash-in-place (WIP) and clean-in-place (CIP) connections for future upgrade (or additional purge gun)

- Built-in 4” connection for future split butterfly valves or other charging systems at base

- Single port glove leak testers

- Weighing balance with external surface mounted display and tare

- With black granite anti-vibration weighing platforms

Related products

Scientific & Laboratory Equipment

Scientific & Laboratory Equipment

Scientific & Laboratory Equipment

Scientific & Laboratory Equipment

Scientific & Laboratory Equipment

Scientific & Laboratory Equipment

AELAB Medical Programming PRP PRF CGF Plasma Gel Blood Low Speed Centrifuge

Scientific & Laboratory Equipment

Scientific & Laboratory Equipment